Edge banding tape related information

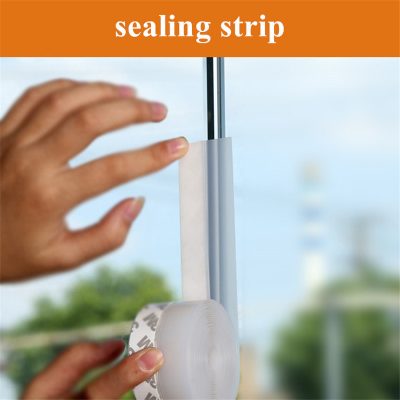

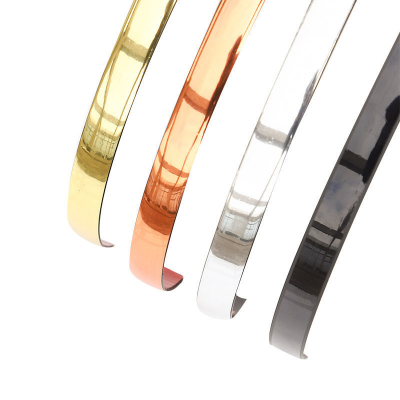

Mainstream edge banding tapes are mainly divided into three types: PVC, ABS, and acrylic. The surface is decorated with wood grain, marble, cloth grain and other choices, which are mainly used for sectional decoration and protection, decoration and beautification of furniture. The main function of the edge banding tape is to seal the cross section of the board so as to prevent the board from being damaged by the unfavorable factors (mainly moisture) in the environment and the use process, and to prevent the volatilization of formaldehyde inside the board, and at the same time achieve the decorative effect.

Edge band classification

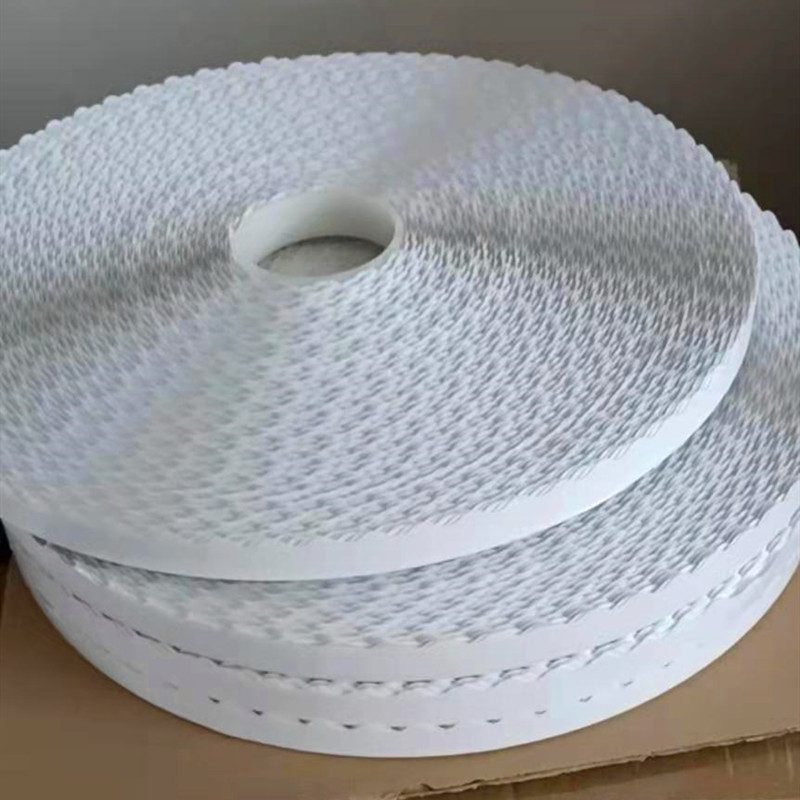

1. PVC edge banding

It is a thermoplastic coil made of polyvinyl chloride as the main raw material, adding plasticizers, stabilizers, lubricants, dyes and other additives, and kneading and pressing together. The surface has wood grain, marble, cloth grain and other patterns and patterns, while the surface gloss is soft, with the realism and three-dimensional feeling of wood; it has a certain degree of smoothness and decoration, and has a certain degree of heat resistance, chemical resistance, corrosion resistance, The surface has a certain degree of hardness.

2. ABS edge banding

It is synthesized from three chemical monomers: acrylonitrile, butadiene and styrene. Each monomer has different characteristics: acrylonitrile has high strength, thermal stability and chemical stability; butadiene has toughness and impact resistance; styrene has easy processing, high smoothness and high strength. From the morphological point of view, ABS is an amorphous material. The polymerization of the three monomers produces a terpolymer with two phases, one is the continuous phase of styrene-acrylonitrile, and the other is the dispersed phase of polybutadiene rubber.