Mastering plumbing with Teflon tape involves understanding its proper application and using it effectively to create reliable and leak-free connections. Here’s a step-by-step guide to help you become proficient in using Teflon tape for plumbing:

Materials You’ll Need:

- Teflon tape (also known as thread seal tape)

- Pipe fittings or connections that require sealing

- Rag or cloth (for wiping threads clean)

Steps to Master Plumbing with Teflon Tape:

- Prepare the Threads: Before applying Teflon tape, ensure that the threads on both the male and female parts of the connection are clean and free from debris, dirt, and old tape residue. Use a rag or cloth to wipe the threads clean.

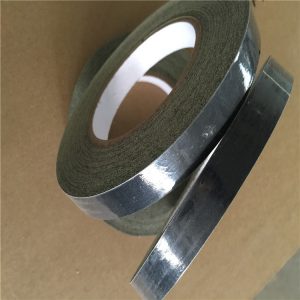

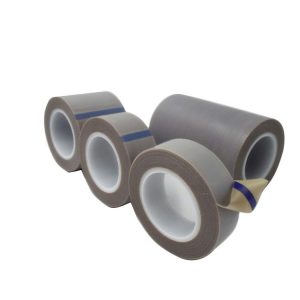

- Choose the Right Teflon Tape: Teflon tape comes in different thicknesses and types for various applications. Choose a tape that matches the material, size, and temperature conditions of your plumbing project. There are tapes designed for general use, high-temperature applications, and specialized materials.

- Start Applying the Teflon Tape: Begin applying the Teflon tape a couple of threads back from the end of the male thread. Hold the loose end of the tape against the thread and wrap it around the thread in the direction of the thread rotation (clockwise) for most threaded connections. This helps ensure that the tape won’t unravel when you tighten the connection.

- Overlap and Wrap Properly: As you wrap the tape around the threads, overlap the layers slightly (about 50%) to ensure a complete seal. Be careful not to stretch or tear the tape while wrapping. Continue wrapping until you’ve covered the entire threaded portion of the pipe.

- Finish the Wrap: When you reach the end of the threads, press the tape down to secure it in place. You can tear or cut the tape using your fingers or scissors. Make sure the last wrap is snug but not too tight.

- Assemble the Connection: Carefully screw the male-threaded part into the female-threaded part, making sure the threads engage smoothly. Do not overtighten, as this can damage the threads or cause the tape to compress excessively.

- Inspect for Proper Sealing: Once the connection is tightened, check for any visible tape protruding from the connection. Trim any excess tape with scissors or a knife, but be careful not to cut the threads.

- Pressure Test (if applicable): If you’re working on a critical plumbing connection, consider conducting a pressure test to ensure there are no leaks. This is particularly important when dealing with water lines or gas lines.

Remember that while Teflon tape is effective for many plumbing applications, there are cases where using pipe joint compound (pipe dope) in combination with Teflon tape might be preferred, especially in high-pressure or critical applications. Always follow plumbing codes and regulations and consider consulting a professional plumber for complex projects.

With practice and attention to detail, you’ll become skilled at using Teflon tape to create reliable and leak-free plumbing connections.