| Product name | Edge banding tape |

| Material | pvc,abs,pmma,acrylic,environment friendly materials according to your requirement |

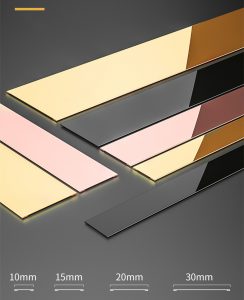

| Specifications | width:9mm-120MM thickness: 0.25mm-3MM |

| surface | olid color collection,woode grain collection,embossing collection,glossy surface collection,linen pitted surface |

| MOQ | 3000 meters per color |

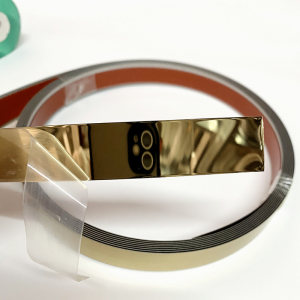

| Packing | 0.25mm-1mm:100 meters/roll |

| 1mm-2mm:100 meters/roll | |

| 2mm-3mm:50 meters/roll | |

| or according to your requirements | |

| Delivery time | about 15-20 days after receiving 30% deposit. |

| Payment terms | T/T,L/C,D/A,D |

| Supply ability | 500000m per day. |

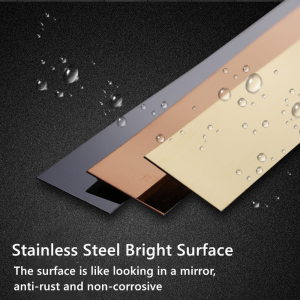

| Temperature | high temperature and low temperature resistant |

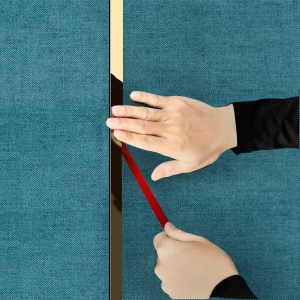

| Feature | Masking paper tape with water-based rubber,soft and fit,

No residue,high adhesion,easy to tear,can be written on. |

Edge banding tape is a kind of adhesive specially used for edge banding of man-made panels. It is a solvent-free thermoplastic adhesive.

Types of edge banding tape

EVA (B*-vinegar*B* copolymer resin) base material hot melt adhesive, this kind of hot melt adhesive can be divided into two types with filler and without filler. Using EVA as the base material is the most common furniture edge banding production technology, and its main limitation is poor heat resistance.

The ambient temperature of panel furniture sealed with EVA hot melt adhesive cannot be higher than 110°C;

POL YAMIDE base material hot melt adhesive, this hot melt adhesive has good heat resistance and fast curing characteristics, the main disadvantage is that it is expensive.

HMPU (Polyurethane) base material hot melt adhesive, it is the best type of hot melt adhesive, it is the guarantee of high-quality sheet edge sealing. It is expensive and requires special methods of use.